Profinet, Siemens to Schneider

Machine Automation Forum

A forum addressing machine automation solutions for the complete machine lifecycle. Including offers like Machine Advisor, Modicon PLC/PacDrive, Lexium or Preventa. Discuss and share knowledge on offers relating to cloud-based service platforms, machine localization and monitoring, industrial operations control, motion products as well as safety function!

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Posted: 2020-04-18 11:53 PM . Last Modified: 2020-11-30 01:40 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-04-18 11:53 PM . Last Modified: 2020-11-30 01:40 AM

Profinet, Siemens to Schneider

Dear community colleagues,

First of all, thank you in advance for reading this post - your valuable time is much appreciated.

I'm a 1. semester automation student who is currently interning at company in Denmark. The company has so far only built their automation solutions on the Rockwell platform along with hardware from Danfoss (VFDs, motion controllers etc), but have decided looking into expanding to Schneider and Siemens.

In that regard, I have taken this small assignment as I think it could be a good fit for my upcoming 1. semester thesis.

The first task is to create a communication between an S7-1500 PLC and a Schneider LMC600 through Profinet.

The correct GSDML file has been installed in TIA Portal (v15.1), and the LMC600 has been assigned in the hardware layout.

My next step will be to send bits and bytes between the two devices to see how they interact with eachother and if there is any bit swapping.

My experience with the TIA environment is not vast and I have absolutely no experience with Schneider.

In that regard, I could really need some sparring on how to carry on with the first part: sending bits/bytes between the two devices. What would the best practices be in this regard?

I know your time is valuable and I'm not looking for you (the community) to hand me the solutions - I just need a push in the right direction and some 'mentoring' along the way. 🙂

If you find the task vaguely explained, please do ask me questions.

Thank you in advance and have a great day. 🙂

- Labels:

-

PacDrive

Link copied. Please paste this link to share this article on your social media post.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-05-03 11:29 PM

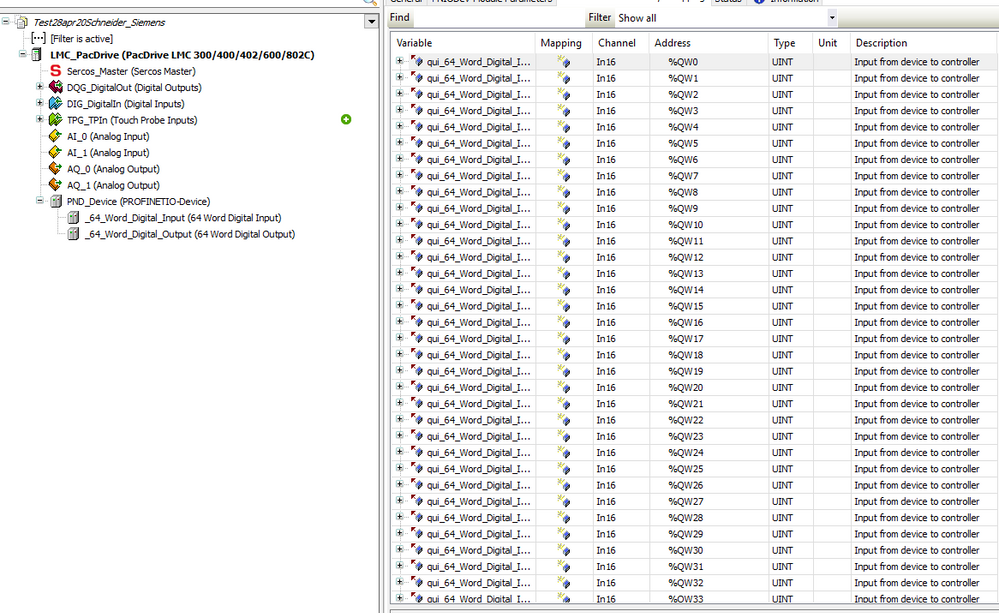

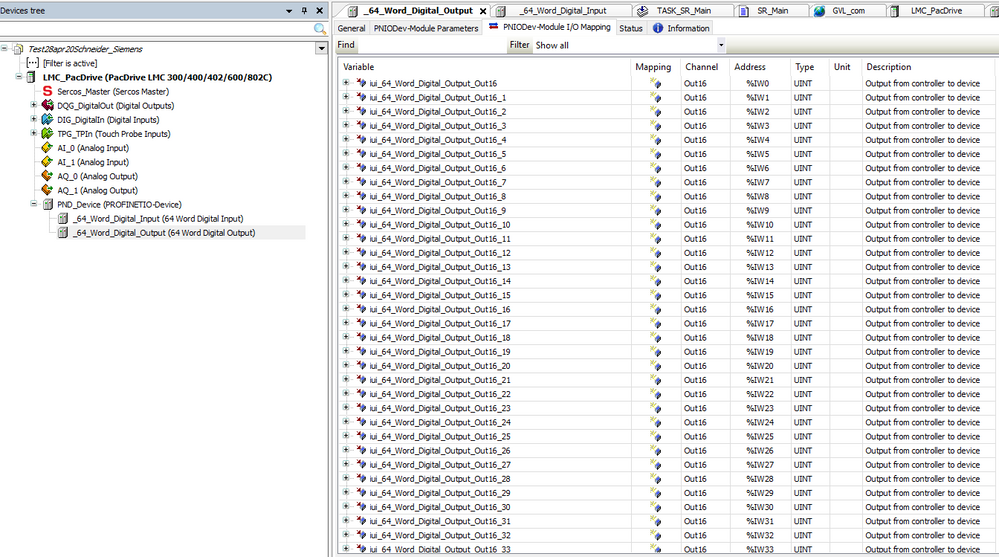

The names of the in out variables are based on the master side. If you look at the addresses you see that the variables with the name output has a %IB address this means that it is an input (even when the name is output). The exception you get is that you are trying to write on a input. Please change your assignment in the PLC -code

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-04-22 07:09 AM

See possible resources on se.com web site https://www.se.com/ww/en/search/LMC600+profinet

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-04-29 12:30 AM

Hello

Peter Aagaard (Danish ADE) is working with you reg. the case, so I think the project is moving forward

Otherwise call us

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-05-01 06:16 AM

Thank you for your reply. Unfortunately, there isn't much info there - only spec sheets. Is there an "easy book" or training manual for Machine Expert? I know Siemens has a lot of documentation for their TIA Portal and S7 PLCs.

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-05-01 10:25 AM

Hello. Actually there is a lot of information out there. Hopefully I can shed some light..

The actual Machine Expert Help file is stored online (see link below)

https://product-help.schneider-electric.com/Machine%20Expert/V1.2/LandingPages/en/index.html

For the sake of learning Machine Expert and getting off the ground running, you might also try YouTube. Lots of helpful videos there. Moreover, in the somewhat recent days Schneider actually made the name change of this software to EcoStruxure Machine Expert from SoMachine v4.3. Both of these IDEs are CODESYS platforms so you might also try that in your web search terms as well. Keep in mind, however, that the LMC motion controllers were actually from a vein of controllers that originitated from ELAU (Schneider acquired them). Up until EcoStruxure Machine Expert, those controllers were actually programmed in a software platform called SoMachine Motion. It was similar to SoMachine v4.3 but had all of the high level motion components and higher level controllers than SoMachine v4.3. EcoStruxure Machine Expert is, now, the vehicle that merged the two under one platform (FAQ link below details this a little).

https://www.se.com/ww/en/faqs/FA380778/

The reason I mention all of this is that knowing this might help you in your efforts to find answers that you're after now that you know where it all came from. Knowing WHAT to search is oftentimes everything.

Mathias

Blue side up.

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-05-02 09:21 PM

Hi MICH!

Originally this assignment (creating connection between LMC600 and S7-1515 via Profinet) was given to a co-student who was on my team. However, he is no longer on the project and I've taken over and started from scratch.

Peter has been great but I also know that your time is valuable. My first approach is to read documents/manuals and solve the issue before contacting support. If I'm stuck for hours/days then I'll go for support. 🙂

Thank you for your time and help. We'll stay in touch.

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-05-02 09:29 PM

Hi AlpenGlow/Mathias,

Thank you so much for pointing me in the right direction. You are absolutely right about knowing what to search is fundemental and crucial for finding answers. My experience in the Schneider IDE is non-existent eventhough I've played around in IndraWorks a little before.

Thank you for your time and help.

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

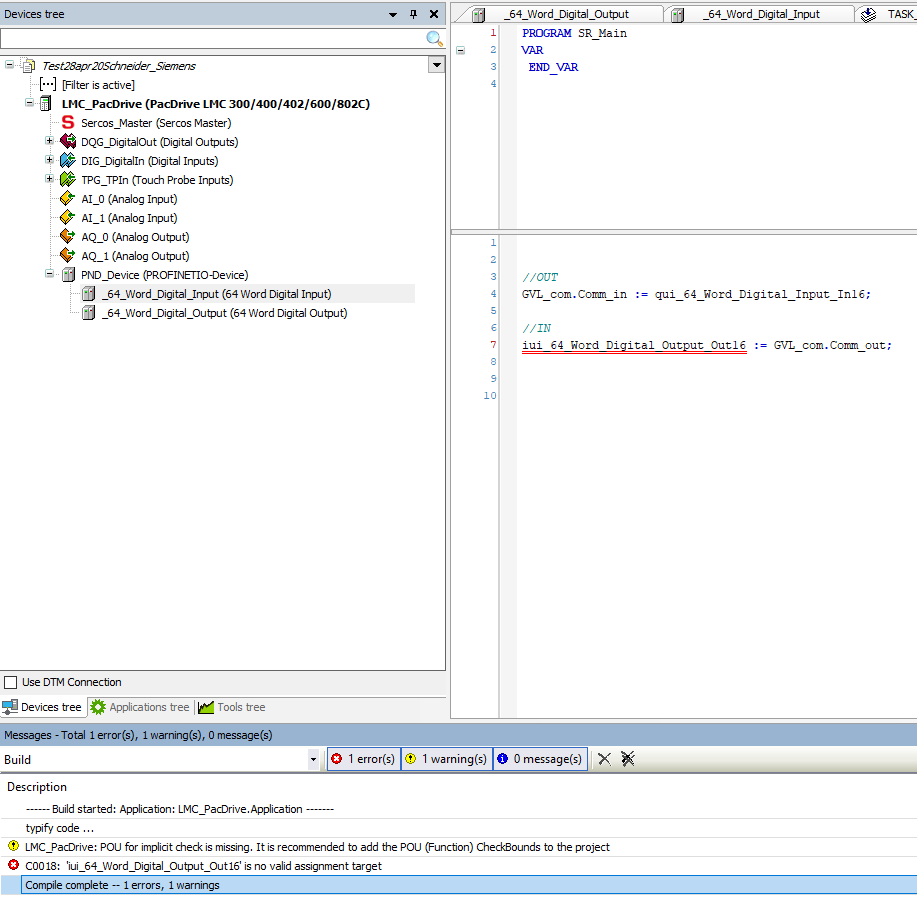

Posted: 2020-05-02 09:46 PM

Hello fellow automation collegues,

Here just a little update on this subject matter.

I've managed to set everything up in TIA Portal and I can go "online" on the devices without any lower level components error and compiling errors in TIA Portal.

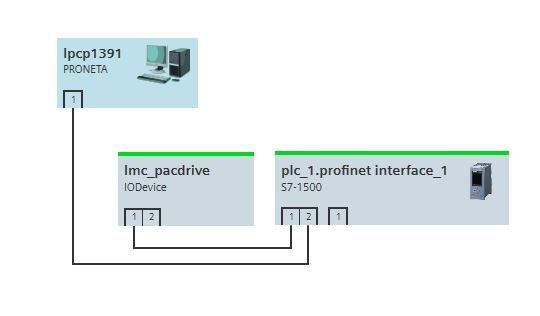

Here's the simple topology:

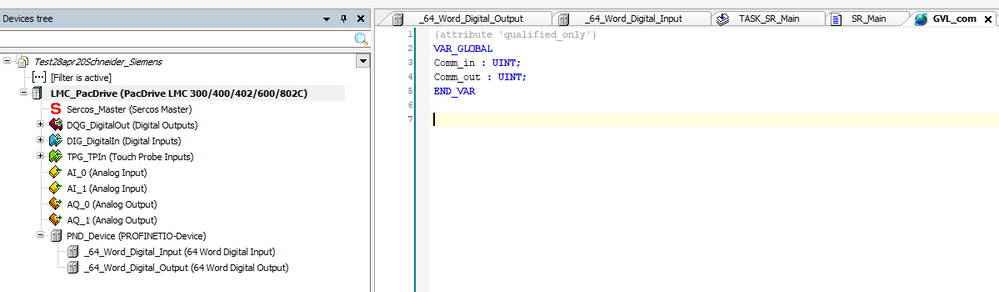

However, I'm getting 1 error in Machine Expert when trying to build/compile my IO-mapping. I'm getting a "invalid assignment target" error. I've looked up in CodeSys but I'm not quite sure what it is.

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-05-03 11:29 PM

The names of the in out variables are based on the master side. If you look at the addresses you see that the variables with the name output has a %IB address this means that it is an input (even when the name is output). The exception you get is that you are trying to write on a input. Please change your assignment in the PLC -code

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-05-04 06:34 AM

Status update:

It works! I can read/write between the S7-1515 and LMC600.

Now, it's time to make the documentation. 🙂

Thank you Ola, Peter and the SE community.

I'm still learning so I'll be back with more questions, no doubt. 😉

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-05-24 10:53 PM

Argh, seems like it fails periodically to receive data from the Siemens end. I'm getting "lower level component errors" in TIA Portal. The S7-1515 CPU is set up correctly but it seems like the LMC600 fails when communicating through Profinet. The strange thing is that I've had it work flawlessly before. But now it doesn't.

Can anyone identify what exactly "Station Name" is in Machine Expert? And in the IP parameter field, is that the IP Address of the LMC600 (192.168.0.102) or the IP-address of the S7 CPU? I haven't been able to find any documentation on this.

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-07-23 01:36 AM . Last Modified: 2020-07-23 01:38 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-07-23 01:36 AM . Last Modified: 2020-07-23 01:38 AM

Hello,

What error did you have in the module diagnostics buffer? I used S7-1200 CPU firmware V4.3 and when I tried to add communication or signal module to CPU, I got this error: "error in lower level component". I'm working on a university project (Università della Svizzera Italiana in Lugano). Can't attach a screenshot here.

Thanks,

Ben

Schneider Electric FAQ | Attachments unavailable https://www.se.com/us/en/faqs/home https://proessays.org

- Tags:

- english

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2024-08-12 03:34 PM

Dear Alpenglow,

I have to communicate LXM32M with s7 300 via profibus.

I can read data of Drive Profile 1/2

And in write parameter of drive profile 1/2, i can write parameters but when it comes to change operating mode(dmControl = 021f) and give jog

command (RefA32=1) via s7 300 drive

It only release brakes and change its state fron 'rdy' to 'run' but did not jog.

One thing suspecious i have observed is it show cross in "_warnlatched but 21" in SoMove but in manual it has multiple warning related to can bus amd others and I am confused is this warning cause my drive to not to jog?

Or is there any thing else?

Link copied. Please paste this link to share this article on your social media post.

Create your free account or log in to subscribe to the board - and gain access to more than 10,000+ support articles along with insights from experts and peers.