Issue

The Sigma IC3-Modbus reports that the Modbus devices are offline.

Product Line

Satchwell Sigma

Environment

- Sigma

- IC3 Modbus

- IC Modbus

Cause

Communications with the Modbus devices has failed, or cannot be achieved.

Resolution

Testing of the IC3-Modbus must be carried out in a systematic way; the points listed below are only as a general guide:

- Confirm that the communications type, (2-wire or 4-wire) is correct for all devices connected to the Modbus 485 communications LAN. The IC3-Modbus only uses a 2-wire RS 485 LAN configuration.

- Ensure that the communications LAN to the Modbus devices is correctly connected.

- Confirm that the overall LAN length does not exceed the RS 485 maximum of 1200M.

- Ensure that the cable has been installed maintaining the 300mm segregation from other electrical services.

- Ensure that the communications cable is a Belden 8762 or similar, and that the cable screening is connected to a good earth at one end only. The other end of the screen should be isolated. (Note: In instances where high frequency noise is present, a 1uF filter can be connected between the isolated screen end and a good earth).

- Configure the Gateway.txt file, ensuring that the comms parameters match those of the Modbus devices. Add one object for the Modbus device nearest to the IC3-Modbus. Download the Gateway.txt to the IC3-Modbus and then warm-start it.

- Observe the IC3-Modbus RS 485 communications TXD/RXD LED's and confirm that the TXD is seen to flash on a regular basis. This will indicate that the Gateway.txt file is configured correctly.

- If the TXD and RXD LED's flash alternatively, then this suggests that normal communications is taking place.

- If the TXD LED does not flash, then this indicates a problem with Gateway.txt file configuration, and it will be necessary to check the "Low level Alarms" on the Sigma Default/Backup server for more information about the problem.

- If the TXD LED is seen to flash on a regular basis, but the RXD does not, then there are four possible conclusions:

- The communications cable between the two points is not continuous, or the cores are crossed.

- The Modbus device number does not match that set in the Gateway.txt.

- The register being requested is not a valid register.

- The Modbus device is faulty.

- Testing a Modbus device using a Modbus simulator.

- Download a Modbus simulator, there are several freeware/shareware products available on the internet.

- Using an RS232/RS485 converter connect directly from the PC/Laptop to the Modbus device. Review the appropriate registers to confirm if the device is working correctly.

- Testing that the IC3-Modbus is sending appropriate Modbus messages.

- Using an RS232/RS485 converter, connect from the PC/Laptop to the IC3 Modbus in parallel with the existing Modbus RS485 comms. Start PocketTerminal32.exe, select “Setup/Communication Ports” and set the comms port to match the Modbus parameters, then select “Display” and select to "Display Hex".

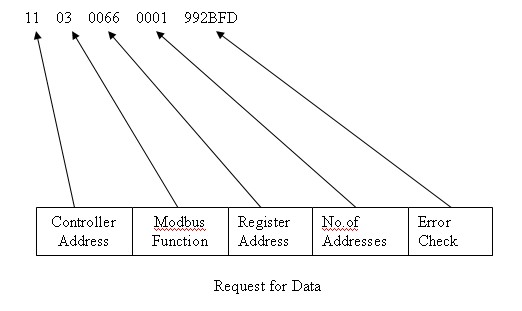

- The trace programme will display blocks of Hex, as shown below. The message shown below is addressed to Modbus device 11 (Decimal 17), it uses function code 3, the register address is 66 (Decimal 96), only this address is required, and the message has an error check.

The message will be shown as 110300660001992BFD which can be split into sections.

- If the controller replies, the complete Request and Reply will appear as:

110300660001992BFD110302142B3698

Request = 110300660001992BFD

Reply = 110302142B3698 Again this message can be split up.

11 = controller address, 03 = Function code, 02 = Number of bytes of data, 142B = Data, and 3698 = Error check.

- Using an RS232/RS485 converter, connect from the PC/Laptop to the IC3 Modbus in parallel with the existing Modbus RS485 comms. Start PocketTerminal32.exe, select “Setup/Communication Ports” and set the comms port to match the Modbus parameters, then select “Display” and select to "Display Hex".

To download a copy of PocketTerminal32.exe please Click Here.