ACRD602 Problem

APC UPS Data Center & Enterprise Solutions Forum

Schneider, APC support forum to share knowledge about installation and configuration for Data Center and Business Power UPSs, Accessories, Software, Services.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:03 PM . Last Modified: 2024-01-29 11:38 PM

ACRD602 Problem

Hello,

I found uncommon problem with my 3 units ACRD602P working as HACS.

The Units stop cooling, and kept in ON and Backup mode, and shown that the Group cooling demand as 0kW, since the temperature in the Datacenter more than the usual and set point which it is 22C.

Link copied. Please paste this link to share this article on your social media post.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:03 PM . Last Modified: 2024-01-29 11:38 PM

Hello Rami. I recommend you call into your local tech support on this issue when you have access to all three of these units either over the web or from the front screen. This issue can be caused by a lot of different factors and may take some adjustments to the setup of the units which is better done over the phone.

A couple of things to look at are: When in HACS mode the unit does not look at the Rack inlet sensor for the cooling demand. the unit is looking at the difference between the return air temperature and the supply air setpoint. It is waiting for the proper delta between these values (determined by your fan speed preference) to know when to turn on. Make sure there are no gaps between the equipment in the racks that will allow the server exhaust air to travel to the front of the rack without going through the cooling unit. If there are gaps this will heat up the rack inlet sensor and cause it to read high. We want all the server exhaust air to be returned to the cooling unit for the heat to be removed.

I am only seeing a 15 kw load in the logs for the group. This is about the minimum amount of heat load to run one of these units. Ideally we would like some more heat load to keep the units running all the time. If you are still building out the room, when more servers are added, this will improve the performance of the cooling units. In the mean time, please call into your local tech support and they can help you change some settings to keep the units running better in the current environment.

Thank you

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:03 PM . Last Modified: 2024-01-29 11:38 PM

Hello Rami. I recommend you call into your local tech support on this issue when you have access to all three of these units either over the web or from the front screen. This issue can be caused by a lot of different factors and may take some adjustments to the setup of the units which is better done over the phone.

A couple of things to look at are: When in HACS mode the unit does not look at the Rack inlet sensor for the cooling demand. the unit is looking at the difference between the return air temperature and the supply air setpoint. It is waiting for the proper delta between these values (determined by your fan speed preference) to know when to turn on. Make sure there are no gaps between the equipment in the racks that will allow the server exhaust air to travel to the front of the rack without going through the cooling unit. If there are gaps this will heat up the rack inlet sensor and cause it to read high. We want all the server exhaust air to be returned to the cooling unit for the heat to be removed.

I am only seeing a 15 kw load in the logs for the group. This is about the minimum amount of heat load to run one of these units. Ideally we would like some more heat load to keep the units running all the time. If you are still building out the room, when more servers are added, this will improve the performance of the cooling units. In the mean time, please call into your local tech support and they can help you change some settings to keep the units running better in the current environment.

Thank you

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:03 PM . Last Modified: 2024-01-29 11:38 PM

Dear Sir/Madam,

I can get all the units configuration, and send them to you if you are interested.

I'm contacting Schneider in Israel, but due to political issues, they can't access the Palestinian Territories. then we will try to solve it remotely.

I made two units to run, because the room is big, please check the attached.

you saw also that the cooling loads not exceeding 15kW, every one min the 2 units working for 2 min.

Also I need your recommendation to connect at least one unit at UPS, because the electricity fails in the winter 2 times a day, so all the cooling units shutdown, what do you recommend?

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:03 PM . Last Modified: 2024-01-29 11:38 PM

Hello Rami.

We usually do not recommend putting DX units on UPS's. This is because the start up demands of the compressor will overload most UPS's unless the UPS is very over sized. This usually makes it impractical to buy a UPS that big. You can work wil the sales teams to find out a UPS that would work with the RD602 and see if it is practical for your situation.

For the running of theses units, as mentioned before the load in the room is low for these units. The ideal fix would be to add more load to the room. This will keep the units on instead of cycling on and off. A few things you can do is to make sure there are no gaps in the server racks to help get the hot air back to the cooling units. Place blanking panels if there are any gaps in the racks. We can also try putting the units to Inrow mode. This will run off the rack inlet temps and may kick the units on quicker to keep those rack inlet temps from spiking.

Thank you

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:03 PM . Last Modified: 2024-02-14 10:11 PM

Dear Sir,

Thank you very much

I Have 2 100kW UPSs with 15% load

I can make two backup units of DX units, and make one working

what is your opinion?

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:04 PM . Last Modified: 2024-01-29 11:38 PM

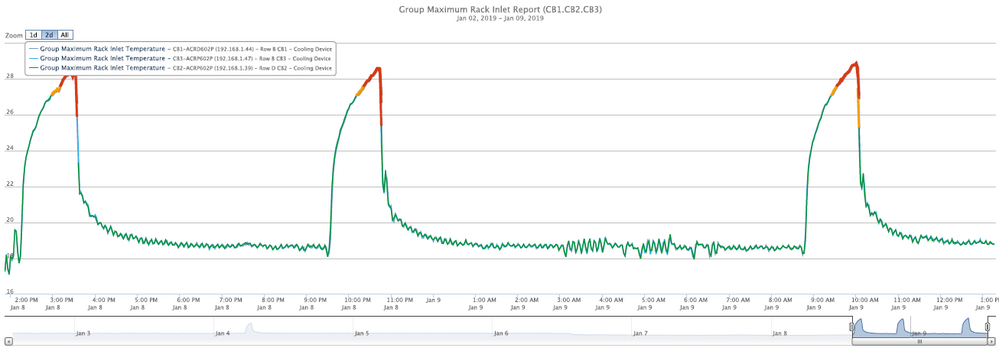

Today the problem occurred once again, please check the attachments to have more information about the problem, also I get a screen shot for configuration and photos for the expansion tanks

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:04 PM . Last Modified: 2024-01-29 11:38 PM

Hello Rami.

From the data logs it looks like there are a couple of the rack inlet sensors that are picking up heat from outside sources. Check the placement of the sensors and make sure they are not picking up heat from servers. Also make sure that there are blanking panels installed in the server racks to make sure there is no exhaust air returning through gaps. For the configuration of the room, is there a HACS containment system installed or is it open to the room?

For the question on using a UPS to power these units, I will have to direct you to the sales team to discuss. They will need to make sure your UPS can take the start up amperage of the cooling unit without getting overloaded on a circuit.

Thank you

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:04 PM . Last Modified: 2024-01-29 11:38 PM

Hello,

If you checked the logs, you will see that the problem occurred in the period of 10:45 - 11:20AM, the Data center manager force on the units.

I have checked the three Units' logs, and found:

CB1:

Supply Air Temp: 23.5C

Racks Inlet: 22-24C

CB2:

Supply Air Temp: 23.5-27C

Racks Inlet: 22-29C

CB3:

Supply Air Temp: 23.5-27C

Racks Inlet: 21-24C

Then the temperature is real one, not occurred because of hot air coming from servers.

if you have a look on Group demand (GrpCoolDmd.kW) was ZERO

I saw that the superheat in some logs is OutOfRange

There are blanking panels, and the hot aisle is totally isolated.

for HACS, yes we are using Hot aisle containment by APC, and Blanking panels.

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:04 PM . Last Modified: 2024-01-29 11:38 PM

Hello Rami.

From the logs the units are turning off as they are satisfying the cooling in the room. It is during this time when they are off that we are seeing the rack inlet temps rise on a few racks. In HACS mode the units do not look at the rack inlet sensors to determine when cooling is needed. The units are looking at the return air temp and the supply air setpoint to try and keep a delta between these two values. What is the fan speed preference set to on the units (this is found under group tab and setpoints). Try raising the fan speed preference (ie if it is set to medium, set it to medium-high). This will lower the delta that the unit is looking for between the return air and the supply air setpoint and will kick on the units quicker. The fans will run at a higher speed as well.

Thank you

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:04 PM . Last Modified: 2024-01-29 11:38 PM

Hello,

the Cooling set point is 22C and the Supply air is 18C, I don't that the units stop working because of Delta Temp, the supply air reached 27C in some units.

The Fan speed set to be Automatic and High

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:04 PM . Last Modified: 2024-01-29 11:38 PM

I would suggest to remove the unit on the side by itself from the group and put that unit to Inrow. This will have that unit look at the rack inlet temps to determine when to turn on. Leave the other two units in a group of 2 with one backup unit in HACS. This will try to smooth out the hot spots so the temps do not rise as much when the units are off after they satisfied their cooling.

Thank you

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:04 PM . Last Modified: 2024-01-29 11:38 PM

Hello,

Since there is no load, then I made one unit working and two backup, I asked the customer to increase the loads, but he can't do that. this load is the maximum.

I change some configuration as:

Supply Air: 18C

Re-Heat: 17C

Cooling Set Point: 22C

What are you recommend to increase the loads?

The unit giving: Excessive Compressor Cycling Condition. warning

many thanks

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:04 PM . Last Modified: 2024-01-29 11:38 PM

Hello. The main way to increase the load is to add in more equipment but it sounds like they are maxed out on their servers. Check to make sure there is no building a/c vent coming into the room. If there is see if you can close it and allow the inrow units to cool the room.

Thank you

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:04 PM . Last Modified: 2024-01-29 11:38 PM

Hello,

It is full isolated

Link copied. Please paste this link to share this article on your social media post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-07-29 11:04 PM . Last Modified: 2024-01-29 11:38 PM

Dears,

the problem solved

I will increase the loads

many thanks

Link copied. Please paste this link to share this article on your social media post.

Create your free account or log in to subscribe to the board - and gain access to more than 10,000+ support articles along with insights from experts and peers.