Ask our Experts

Didn't find what you are looking for? Ask our experts!

Share Your Feedback – Help Us Improve Search on Community! Please take a few minutes to participate in our Search Feedback Survey. Your insights will help us deliver the results you need faster and more accurately. Click here to take the survey

Schneider Electric support forum about installation and configuration for DCIM including EcoStruxure IT Expert, IT Advisor, Data Center Expert, and NetBotz

Search in

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-07-02 11:05 AM . Last Modified: 2024-04-10 12:40 AM

Hi All!

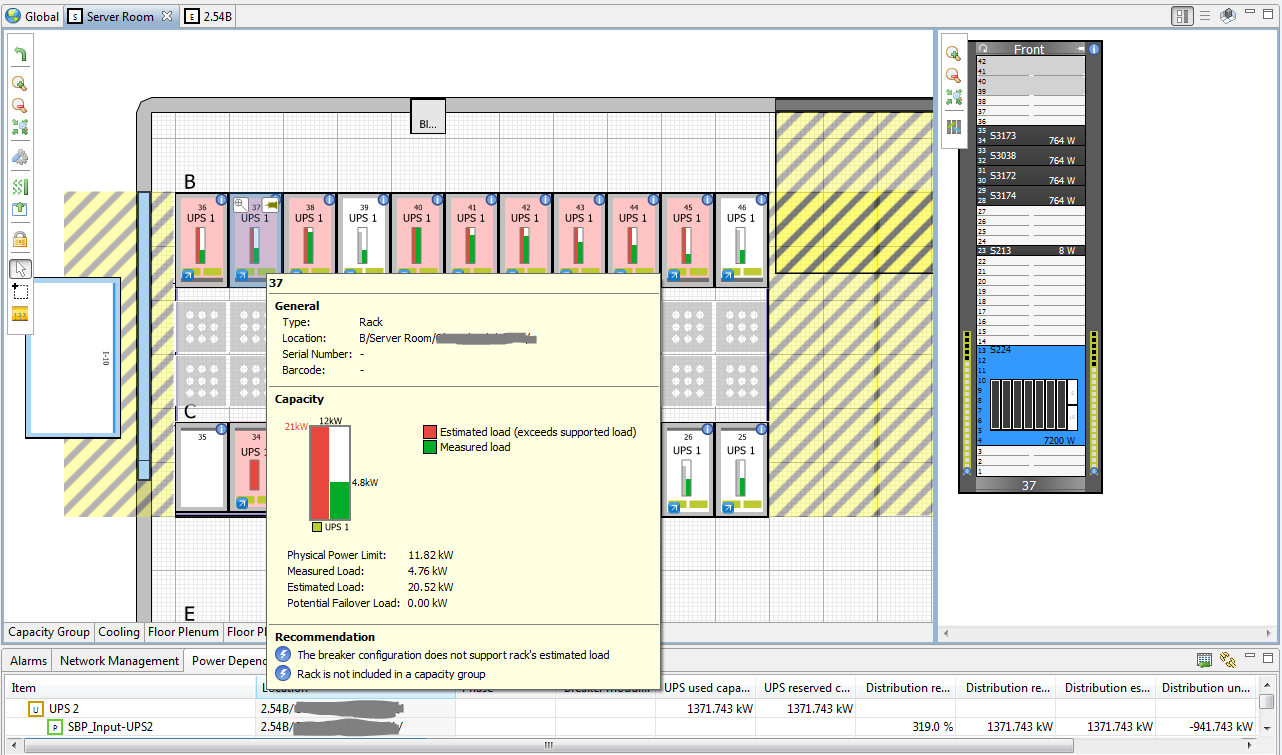

We have an interesting issue with Estimated Load calculation.

DCO calculates Estmated Load more then double rack equipment's nameplates sum.

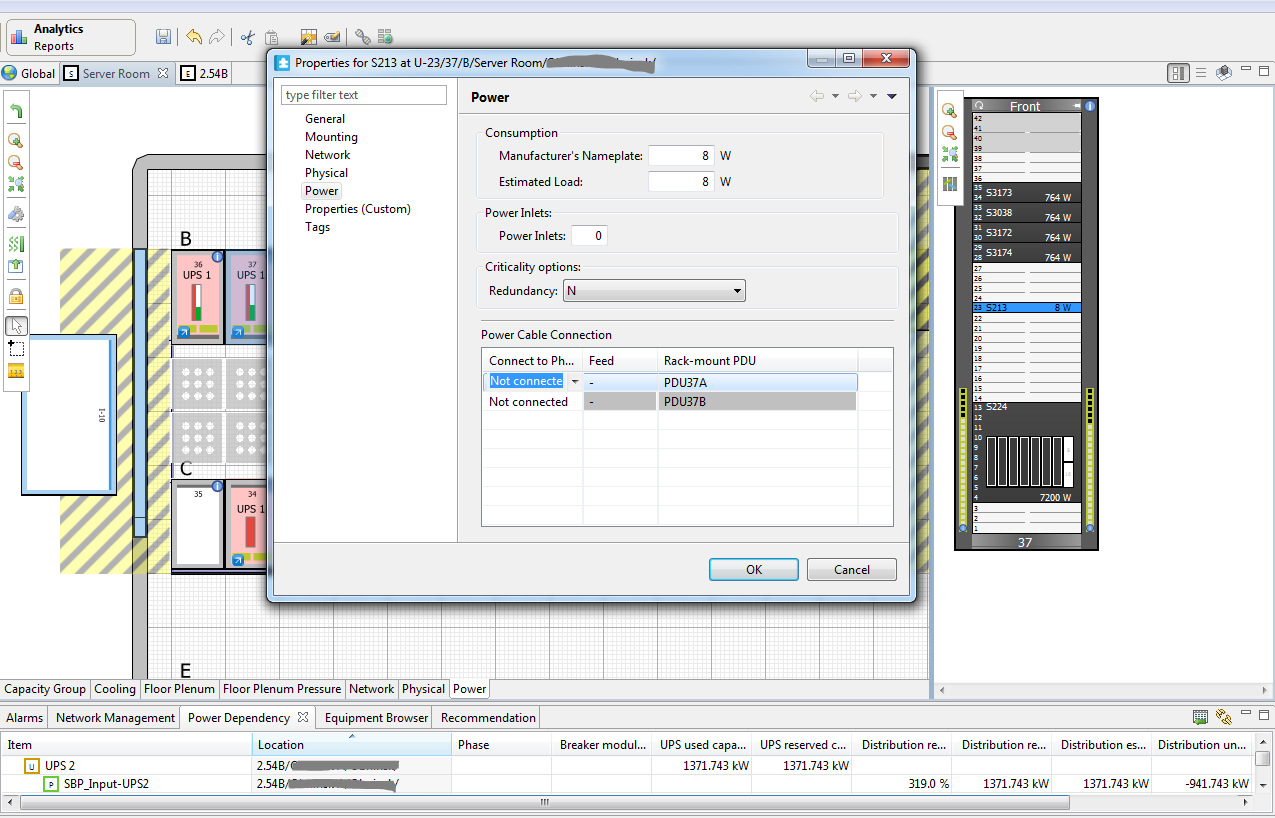

It's look like something wrong with server to rPDU connections. But all servers connections to rPDU's configured correctly - with 2 power cable connection, 2 power inlets and Distribution redundancy.

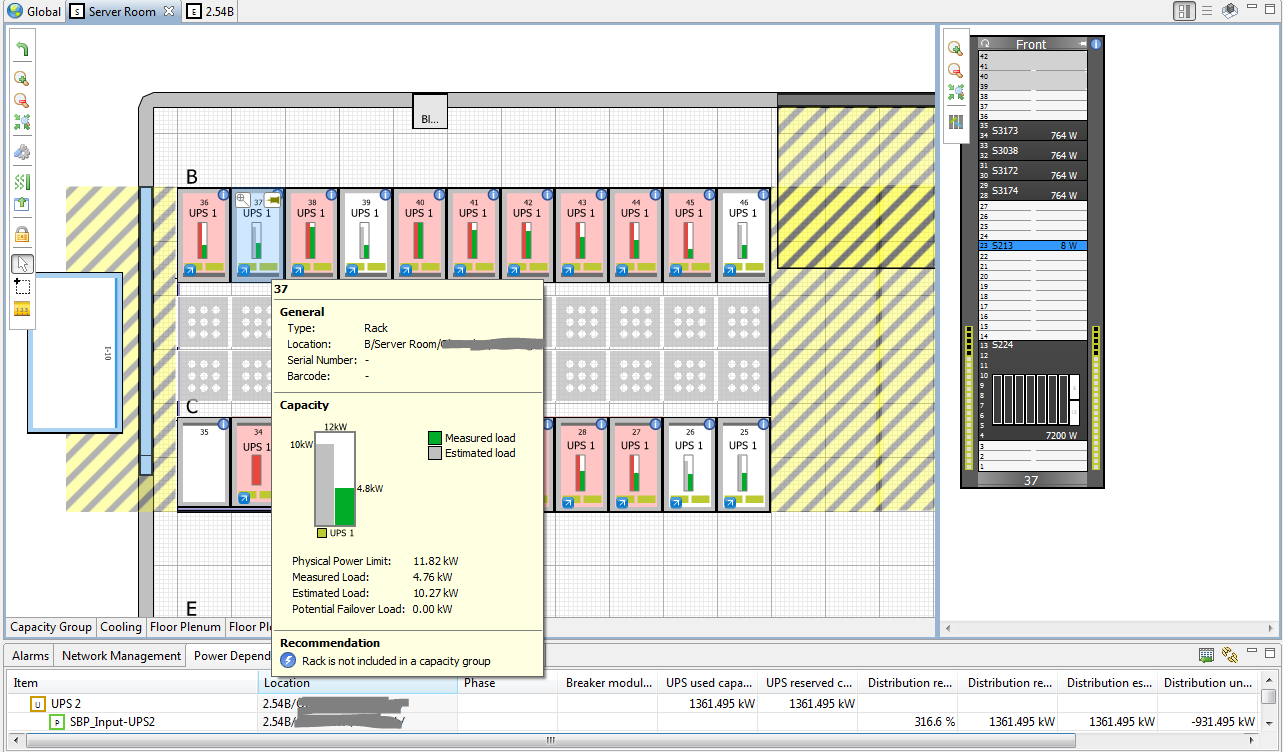

Now, if I set power cable connection to "Not connected" for any server in rack, DCO calculate corrects values:

I can also add "dummy'' server with 0W power and no power connection and it works similary. This is my workaround for a while.

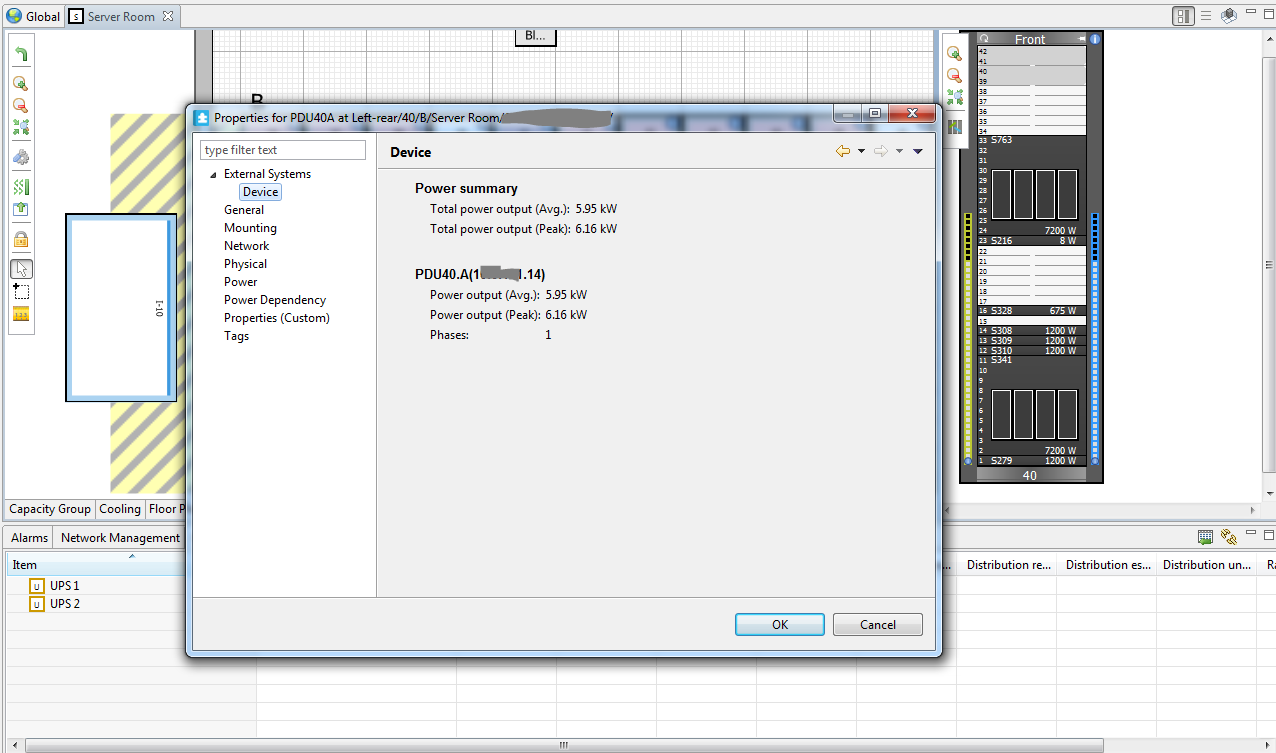

Also, there is some problems with Measured Load values. It's also much bigger (almost twice) than measurements in DCE.

Any ideas?

Not all racks affected with this issue, some calculations are close to correct values.

Some setup details:

Originally DC was modeled on DCO 7.3.6, racks was populated via import from Excel workbook feature. Now customer bought Capacity license, we upgrade DCO server to 7.4.5 version and try to properly configure it.

May be there are some artifacts in database after upgrade?

(CID:94602526)

Link copied. Please paste this link to share this article on your social media post.

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-07-02 11:06 AM . Last Modified: 2024-04-10 12:40 AM

Hi Valentin,

I believe DCO is calculating correct in this case. I will try to explain what is going on.

As I understand the setup should be using DN (distribution redundancy)? If that is the case it is very important that this is set at the Capacity Group level as well as server level and not only at server level. If this is only set at server level DCO will still tread the setup as normal N setup seen from a capacity point of view (since it is not configured different). This will lead to results that are strange since the capacity calculator will be very pessimistic in calculating the load in the rack (you see more than double of the estimated load).

If the right configuration is done in the capacity group to use DN then you will see in racks that have different phases that the estimated load of the server will be shared between the phases and there will be a failover load on the rack (that having different phases in the rack). The failover load is done in order to make sure that any of the RMPDUs always can fall out and the other take over, both at RMPDU (breaker) level, PDU and UPS level.

However in your case I would recommend using the measured data. The measured data is used in a setup where servers are NOT connected to the RMPDUs. When connecting cables to the RMPDU it is telling the capacity calculator that the cable connections should be used to divided the load between RMPDUs. When no connections (or one or more servers miss connection) the load is divided using the weight of the measured data coming from DCE. (this is why the "dummy" server seemed to "work" it simply made a change in the strategy used for applying the estimated load).

The Adjusted Nameplate/Estimated load of the device is taken directly. There are no factor or calculation done based on number of power supplies or similar.

I would not expect any side effects by having upgrade from a 7.3.6 with excel imported data to 7.4.5. Since capacity related information is added with 7.4.5 as well as power configuration most likely the same (or at least is being verified) then it should be fine.

It however looks like there is an issue with the measured data coming from the RMPDUs.

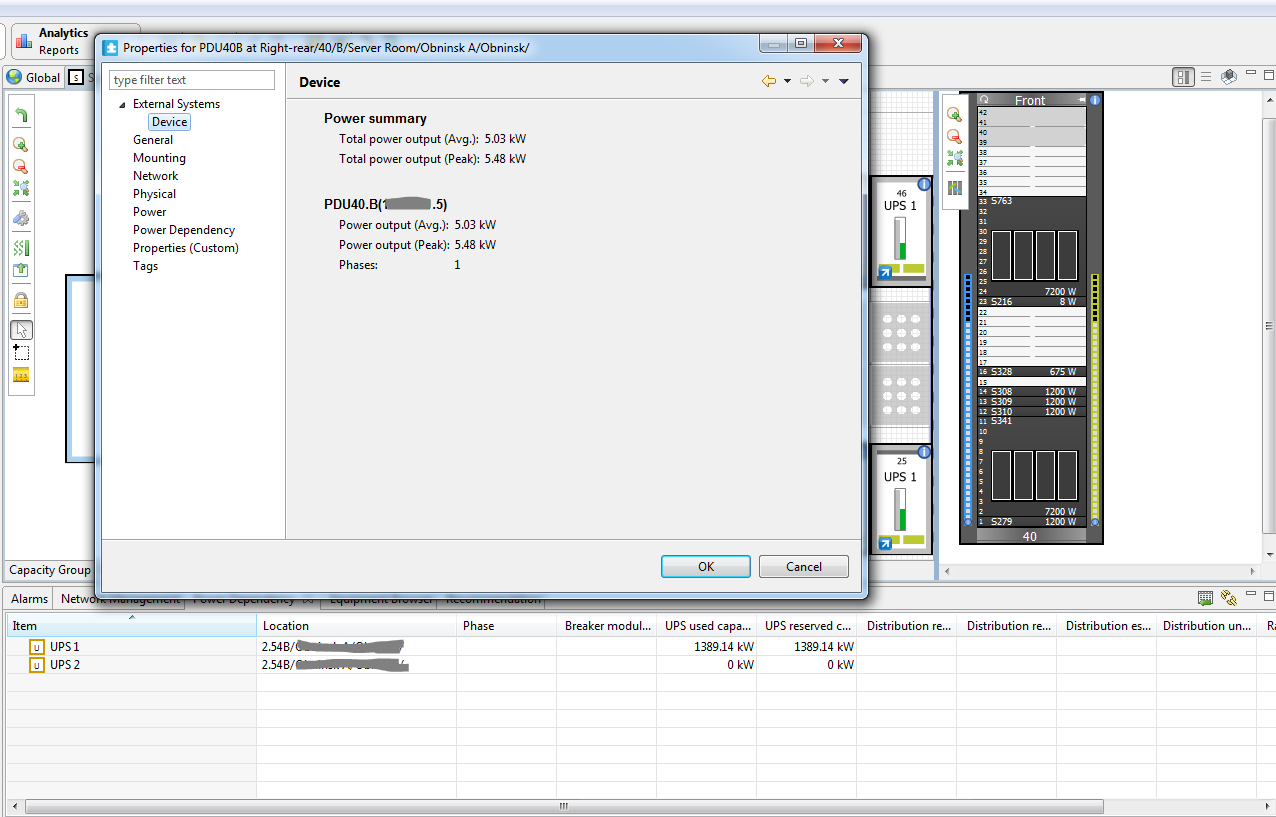

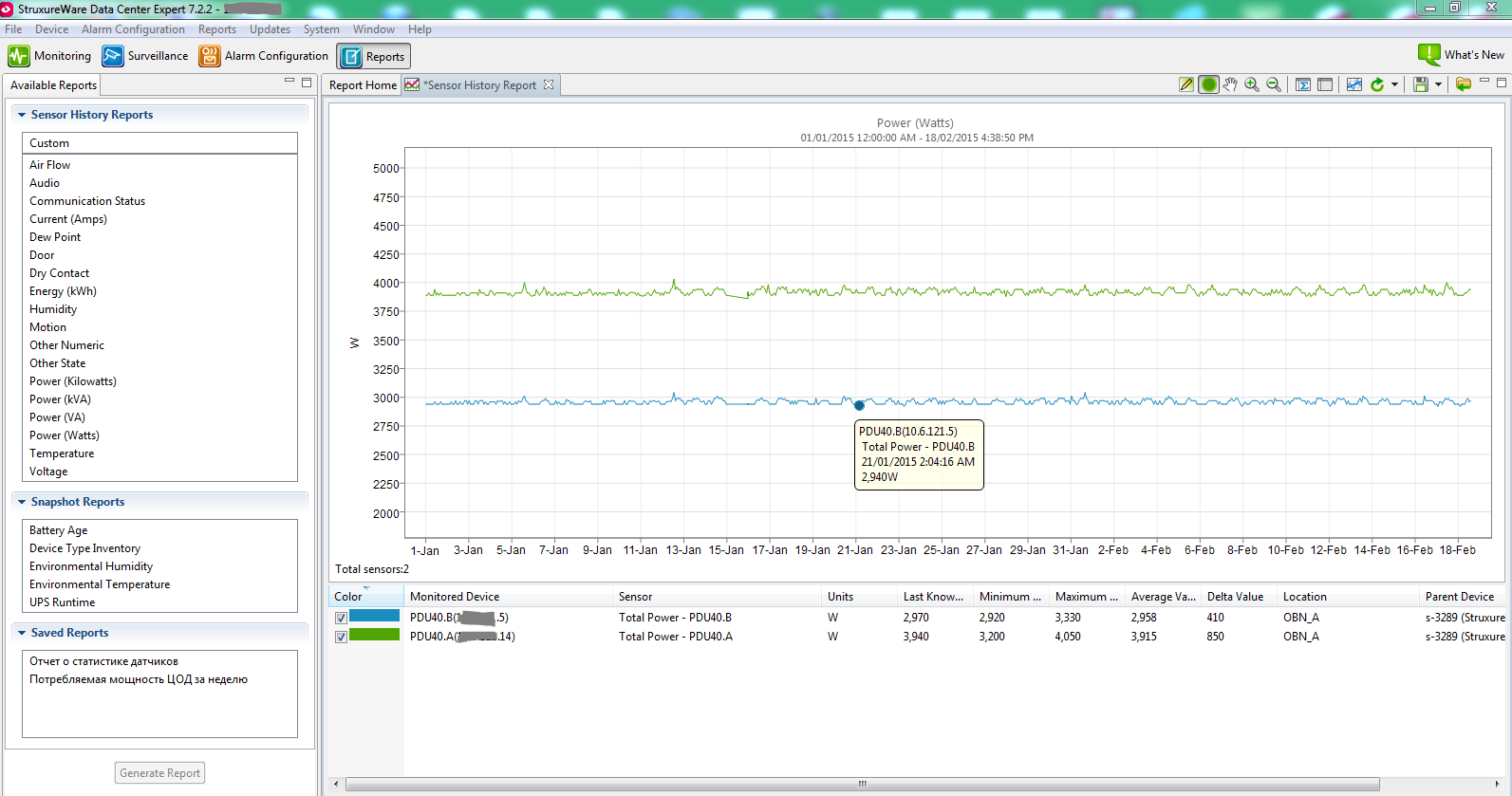

You are absolutely right in looking at the RMPDUs over 30 days and then the average and maximum (Peak) values are what is used in DCO. It seems like the RMPDUs are single phase? Which model is being used?

Have you looked into if there are any other sensors in DCE from the RMPDUs that are reporting the numbers you are seeing in DCO? It might be an issue with wrong sensors being used in DCO. This should then be corrected in the DDF if that is the case.

If possible you could also try to remove the association in DCO, delete and rediscover the device in DCE and then associate the device again in DCO. That will cause new data to be transferred from DCE to DCO and DCO will create a new object of the device to provide data into.

(CID:94602818)

Link copied. Please paste this link to share this article on your social media post.

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-07-02 11:06 AM . Last Modified: 2024-04-10 12:40 AM

Hi Valentin,

Regarding the Estimated load:

The way we configure power redundancy is, if it's N/N+1 redundancy, you have to connect 1 rack PDU(considering the redundancy at Source end) , which gives you the estimated load on the rack as per the Manufacture's Nameplate ratings on the devices within the rack. If the redundancy is DN/DN+1, you need to connect to two Rack PDUs(Considering the redundancy at the distribution end), in this case the UPS will reserve additional Nameplate value of the Rack for the load & you shall see the Estimated load-double than the actual Nameplate values. You should visit this link to know more about the redundancy configuration:

Regarding the Measured Load:

What DCO displays is 'Measured Peak', so it's likely not to be equal to the measure load. The 'Average Output' in DCO comes after averaging the latest 30 days data from DCE.

Please note: DCO is a planning tool, for realtime monitoring we still recommend DCE.

(CID:94602553)

Link copied. Please paste this link to share this article on your social media post.

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-07-02 11:06 AM . Last Modified: 2024-04-10 12:40 AM

Hi Aniruddha, "in this case the UPS will reserve additional Nameplate value of the Rack for the load" - why the extra load reserves on the UPS if it's not rated for and clearly configured as N(N+1)? - what would happen for 2N redundancy, would it reserve more than 2xNameplate value? Thanks

(CID:94602812)

Link copied. Please paste this link to share this article on your social media post.

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-07-02 11:06 AM . Last Modified: 2024-04-10 12:40 AM

Hi Aniruddha! Thanks for you answer! But why we need to reserve additional power if server still connected to the same UPS??? What difference if it connected to one PDU or to two PDU, it still consume same power? I can't understand this and can't explain it to customer. I agree, that if we use 2N, we need to reserve additional power for failover, but if we use DN - it might be the same, I guess. Only way is if "Manufacturer Nameplate" value in DCO is not a server total power draw but a nominal power of each server's power supply, then this calculation will be correct. Could you clarify how DCO calculate server power draw? Total power = Manufacturer nameplate value or Total power = Manufacturer Nameplate value x power supply number? Regarding Measured Load: What values displays in "Measured Load" field? If it is not measured load from PDU - what is this? Why this values much bigger than values from DCE? If you look at last screenshot, you will see measurements for last 30 days and its average value also smaller than "Average Output" in DCO.

(CID:94602641)

Link copied. Please paste this link to share this article on your social media post.

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-07-02 11:06 AM . Last Modified: 2024-04-10 12:40 AM

Hi Valentin,

I believe DCO is calculating correct in this case. I will try to explain what is going on.

As I understand the setup should be using DN (distribution redundancy)? If that is the case it is very important that this is set at the Capacity Group level as well as server level and not only at server level. If this is only set at server level DCO will still tread the setup as normal N setup seen from a capacity point of view (since it is not configured different). This will lead to results that are strange since the capacity calculator will be very pessimistic in calculating the load in the rack (you see more than double of the estimated load).

If the right configuration is done in the capacity group to use DN then you will see in racks that have different phases that the estimated load of the server will be shared between the phases and there will be a failover load on the rack (that having different phases in the rack). The failover load is done in order to make sure that any of the RMPDUs always can fall out and the other take over, both at RMPDU (breaker) level, PDU and UPS level.

However in your case I would recommend using the measured data. The measured data is used in a setup where servers are NOT connected to the RMPDUs. When connecting cables to the RMPDU it is telling the capacity calculator that the cable connections should be used to divided the load between RMPDUs. When no connections (or one or more servers miss connection) the load is divided using the weight of the measured data coming from DCE. (this is why the "dummy" server seemed to "work" it simply made a change in the strategy used for applying the estimated load).

The Adjusted Nameplate/Estimated load of the device is taken directly. There are no factor or calculation done based on number of power supplies or similar.

I would not expect any side effects by having upgrade from a 7.3.6 with excel imported data to 7.4.5. Since capacity related information is added with 7.4.5 as well as power configuration most likely the same (or at least is being verified) then it should be fine.

It however looks like there is an issue with the measured data coming from the RMPDUs.

You are absolutely right in looking at the RMPDUs over 30 days and then the average and maximum (Peak) values are what is used in DCO. It seems like the RMPDUs are single phase? Which model is being used?

Have you looked into if there are any other sensors in DCE from the RMPDUs that are reporting the numbers you are seeing in DCO? It might be an issue with wrong sensors being used in DCO. This should then be corrected in the DDF if that is the case.

If possible you could also try to remove the association in DCO, delete and rediscover the device in DCE and then associate the device again in DCO. That will cause new data to be transferred from DCE to DCO and DCO will create a new object of the device to provide data into.

(CID:94602818)

Link copied. Please paste this link to share this article on your social media post.

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-07-02 11:06 AM . Last Modified: 2024-04-10 12:40 AM

Many Thanks!

Issue was fixed after configuring Capacity Groups.

(CID:94603072)

Link copied. Please paste this link to share this article on your social media post.

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-07-02 11:06 AM . Last Modified: 2023-10-31 11:32 PM

This question is closed for comments. You're welcome to start a new topic if you have further comments on this issue.

Link copied. Please paste this link to share this article on your social media post.

You’ve reached the end of your document

Create your free account or log in to subscribe to the board - and gain access to more than 10,000+ support articles along with insights from experts and peers.