Issue

- Troubleshooting 2-Output PWM on a Xenta 102-AX

- Floating actuator for heating applications (hot water valve)

Product Line

TAC Vista

Environment

- Xenta 102-AX

- PWM_2 floating hot water valve actuator

Cause

Multiple causes legitimately keep the hot water valve two-out floating control from stroking.

Resolution

The Xenta 102-AX controller supports auxiliary heat with two outputs. Both outputs can be utilized in a 2-output pulse width modulated (PWM) signal for control of floating actuators. This document suggests troubleshooting techniques to help narrow down the cause of improper operation of these hot water valve outputs.

Start with Universal Output #2

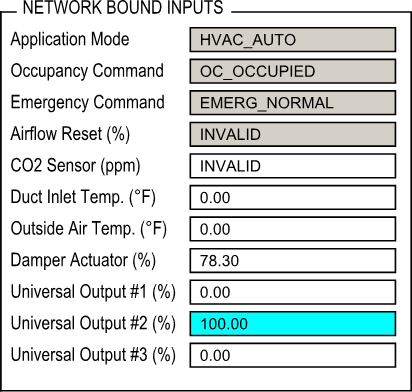

On the Status tab of the 102-AX Plug-in, each of the universal outputs are listed under the “Network Bound Inputs” column.

The output that represents the 2-output PWM is Universal Output #2 only. Even though output #3 is involved in the process, only #2 in the Plug-in represents the actuator position. The first thing to do is override the output to three different positions: 0, 50 and 100%.

Cycling between three different values ensures the actuator is actively stroking. Forcing the valve to 100% will cause the open signal to energize for the full stroke time (throttling range) of the actuator, after which it will be de-energized. Wiring problems discovered after this time period has elapsed would require the output to be forced to 0% and then back to 100% to energize the open signal for the full stroke time again.

If the valve strokes correctly, then the unit parameters, wiring, and actuator are all correctly configured. Skip directly to the chapter entitled “Overriding the Output Successfully Stroked the Actuator.” If the valve did not successfully stroke, proceed to the next chapter where three possible problems are addressed.

Overriding the Output Failed to Stroke the Actuator

There are three main reasons why overriding the output would fail to stroke the actuator.

Unit Parameters

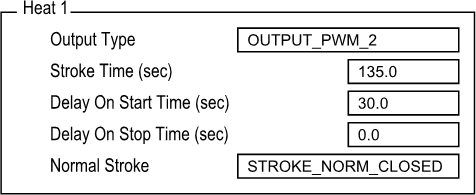

The Unit Parameters tab of the 102-AX Plug-in is where Universal Outputs #2 and #3 are configured to work in tandem to accomplish 2-Output PWM control of a floating actuator. Heat 1 configures both outputs when OUTPUT_PWM_2 is selected. There is no need to configure Heat 2. Changes to Heat 2 will have no effect on the heating operation.

Make sure the output type is set for OUTPUT_PWM_2. The stroke time should match the manufacturer’s documented stroke time of the actuator. Delay on start and stop are dictated by user preference or customer specifications. Normal Stroke should be set for normally closed.

Wiring

Check the wiring of the actuator to the 102-AX. It should be wired as follows:

| Point | Label | Terminal | Actuator |

| Universal Output #2 | V2 | 15 | OPEN |

| Universal Output #3 | V3 | 16 | CLOSE |

| Ground | G0 | 13 | COM |

Actuator

The last step to troubleshoot an issue with the actuator not moving is to test the actuator itself. This can be done by jumping out the open or close leg of the actuator to 24Vac power. If the actuator still does not move then it is faulty and should be replaced.

Overriding the Output Successfully Stroked the Actuator

If overriding the output causes the valve to move accordingly, then the configuration of the output and the physical configuration are all correct. The 102-AX controller logic is not calling for the valve to open. There are a number of reasons why this might be occurring.

The Basics

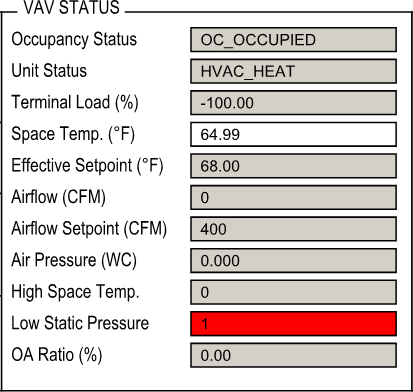

The 102-AX must be in a heating mode to open the valve (cooling mode will close the actuator). It may be displaying either HVAC_HEAT or HVAC_MRNG_WARMUP. The space temperature must be below the effective setpoint to be in heat mode and will generate a negative terminal load down to -100%. The terminal load will equal the heating valve position.

Check that the heating/cooling setpoints and heating/cooling bands are set such that no overlap in the two modes occurs. Heating/cooling bands must be greater than 0°.

Hardware Configuration

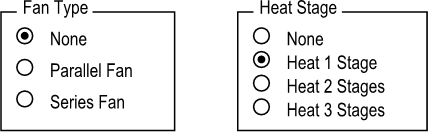

If the 102-AX is not configured for a sufficient number of stages of heat, it will not cycle the valve. If there is no fan, then only one stage of heat needs to be defined. However, if a fan is defined, then there needs to be at least two stages of heat, because the fan is considered the first stage.

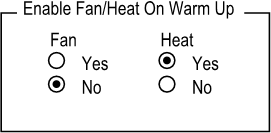

If the heating valve is to be utilized in morning warm up mode (when the duct inlet temperature indicates that the air handling unit is providing central plant heat), then the hardware configuration must state that supplemental heat is allowed during warm up.

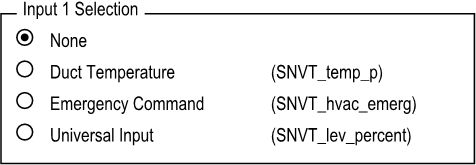

If a supply temperature sensor is wired to Universal Input #1, it could be that it is sending the VAV into morning warm up mode when the heat is enabled, and thus, disabling the heat. If this is the case, there are two options. Universal Input #3 can be used instead and set as an outside air temperature. Alternatively, Universal Input #1 can be configured as "None."

Setting Input 1 Selection to "None" will not disable the reading of the sensor. UnivIn1_Sense.nvoAuxTemp1 will continue to report the duct supply temperature. Setting it to "None" disables the signal from affecting the internal logic – preventing the 102-AX from entering morning warm up mode.

Note: If the VAV is already in morning warm up mode when the input is set to "None," the box will remain in morning warm up mode. Override the input temperature to something below room temperature prior to changing the input selection.

Application Mode

The SNVT input VAV_Controller.nviApplicMode can allow a supervisory controller to override the current mode of the VAV. Upon receipt of a new application mode, the 102-AX will encounter a brief synchronization period where the terminal load is held to 0%.

If the SNVT is being sent from a data manager, and the period on the output SNVT in Menta is set to 60 seconds, then the 102-AX will zero out the terminal load every 60 seconds, preventing proper operation. Set the SNVT output to a period of 0 seconds, and it will only write a new value on change and allow proper external control of the mode.

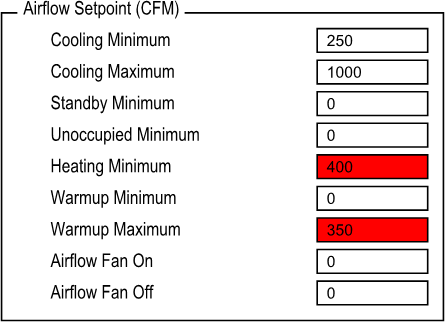

Airflow Setpoint

The Warm up Maximum airflow setpoint must be greater than or equal to the Heating Minimum airflow setpoint. If this is not the case, then the airflow setpoint will default to the unoccupied flow setpoint (typically 0 CFM) any time the VAV is in heat mode, and the heating output will not be utilized. This can be easily overlooked in applications where Warm up Mode is not being used, but this one parameter must still be set. This is fixed in the Xenta 102-AX firmware v2.18.

Actual Airflow

In order for the heating outputs to be energized, the airflow must be at least 80% of the minimum heating airflow setpoint. This is hard coded into the controller and cannot be disabled.

The only way to remove the interlock is to set the minimum heating airflow setpoint to 0 CFM; however, in this situation, the VAV will close the damper in an attempt to provide 0 CFM of airflow. The heating will modulate without any airflow at that point.

Check on the VAV Status tab of the 102-AX plug-in to compare the airflow to the airflow setpoint. If the box cannot provide the necessary 80% of setpoint or there is no airflow available during the commissioning stage, lowering the airflow setpoint can allow checkout to continue.

This 80% airflow requirement is looking at the on-board flow sensor of the Xenta 102-AX. If the flow value is coming from another controller on the network via the nviBoxFlow SNVT, the heat will be disabled. The nviBoxFlow input will override flow values for damper control, but heating outputs will ignore it. In this situation, setting the pressure offset (UCPToffsetPress) to 1” will bypass the limitation. This will be fixed in the Xenta 102-AX firmware v2.18.

Wrap Up

If everything is configured properly physically and in the 102-AX Plug-in, then the box should be stroking the valve to maintain the space temperature setpoint.

Disclaimer

The information contained in this document is subject to change without notice. It is also subject to change with versions of TAC Xenta 102-AX. If further assistance is required, or if you would like to add to steps suggested here, call or email Schneider Electric Product Support.