Ask our Experts

Didn't find what you are looking for? Ask our experts!

Get support to configure, troubleshoot, update or upgrade your motor management solution built with Altivar variable speed drives and Tesys devices to start, control, protect and monitor Low Voltage and Medium Voltage motors and loads, covering direct start, soft start and variable speed control.

Search in

Posted: 2021-05-07 10:42 AM

Link copied. Please paste this link to share this article on your social media post.

Posted: 2021-05-07 10:42 AM

Circuit breakers enable Process Industry Operators, such as O&G, Chemicals or MMM, to benefit from smaller switchboards and to digitize their power system, yet ensuring similar or superior protection level as fuses.

You may wonder what’s new and why sharing again a blog post on that topic?

Because fuses are still specified by a significant fraction of Operators and only part of the circuit breakers benefits are considered when making the choice.

Focusing on product-to-product comparison leads to miss some key circuit breaker benefits.

Fuses are the legacy design with good performances for short circuit protection. No discussion there, they do the job!

On circuit breaker side, design and performances have been drastically improved since Molded Case Circuit Breaker (MCCB) introduction on the market, reaching similar and sometimes better electrical performances than fuses.

In addition to over-current protection, circuit breakers are fully part of electrical digital systems for alarming, monitoring and control.

But the game changer is the large savings circuit breakers bring at LV switchboard level: up to 15% on the footprint and 10% on costs.

In addition, fused switch disconnectors have other negative implications for operations: spare part management, cost of spares, risk when replacing blown fuses, cost and environmental impact of higher losses.

At product level, “5 Reasons to Choose Circuit Breakers Over Fuses” blog post well explains their advantages.

In the MCC context, I would underline:

In the 2020s, it is not only a matter of money but also to reduce CO2 footprint during operations

But all circuit breakers do not have same design: fast breaking solutions should be specified to generate high current limitation and reduce let-through energy

LV MCC footprint and costs

Fuses are often perceived as a cheaper alternative to circuit breakers

That could be challenged, especially from a TCO or Totex perspective, but this is not the key point.

The experience gained in supporting Customer projects clearly shows the smaller MCC footprint with circuit breakers, when dealing with mid to large size MCCs.

And that smaller footprint leads to reduced cost at switchboard level, not to mention cost reduction to the electrical rooms.

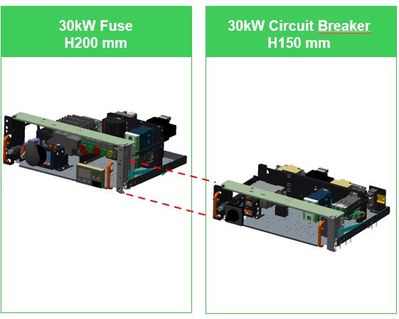

For example, a 30kW motor feeder typically requires a 200mm drawer with fuse switch combination, vs a 150mm drawer with a circuit breaker.

This lead up to 15% footprint reduction and 10% costs savings at complete switchboard.

Additionally, let me share one case study for a large LNG train, across 17 MCC switchboards and 250+ cubicles. Fuses would lead to:

If you are not yet convinced, leave your MCC specifications open to both technologies so as to leave to vendors to select the most suitable alternative and have you to benefit from latest enhancements from circuit breakers!

Link copied. Please paste this link to share this article on your social media post.

You’ve reached the end of your document

Create your free account or log in to subscribe to the board - and gain access to more than 10,000+ support articles along with insights from experts and peers.