Ask our Experts

Didn't find what you are looking for? Ask our experts!

This forum is addressing industrial automation design & engineering, operations, asset performance, cyber security and digital transformation for Plants & Machines.

Search in

Posted: 2020-12-03 07:37 PM

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-12-03 07:37 PM

Digital Safety Applications

Schneider Electric (SE) is more than just a hardware supplier for Safety Systems. SE provides advanced Digital Safety Applications to deliver additional value. SE has a variety of Safety Applications that can help customer to digitalize their data, reduce effort, saving time, increase performance and enhance profitability.

|

In the Design and Build phase: |

|

Triconex Safety Validator (TSV) is a TÜV Certified application for specific use with Triconex logic. TSV is designed to meet specific requirement of IEC-61511 (e.g. validation and proof testing etc.). It automatically tests logic functionality, delivers higher test integrity, repeatable accuracy and detailed reporting. It helps in removing human error and reduce FAT, SAT, Start-up. In addition, it also provides value during the Operate and Maintain phase to validate changes and perform verification during turnaround time. |

|

|

In the Operate and Maintain Phase: |

|

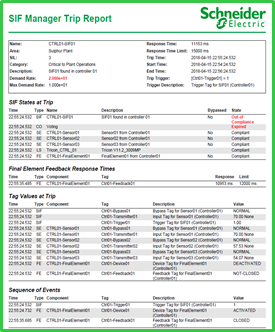

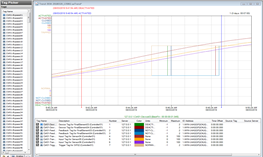

SIF Manager Trip Analyser is mainly used for trips and outages. It provides automatic trip reports, with detail of every element, timestamp from the controller and full SOE integrated in the report; Historical trends of status of all elements of the SIF/Loop in a time window both pre- trip and post-trip; complete history of previous trip events for the same SIF/Loop to compare past trip performance against current trip event. It also provides critical trip event details and trip investigation history audit trail. Having instant on-line access to the performance of every SIF/Loop during the trip event (as well as access to the trip history of the SIF) can significantly reduce the trip investigation duration, allowing he customer to re-start production up to 30% faster than before – helping them recover lost opportunity production, increase revenues, increase plant uptime and improve plant efficiency. |

|

|

In addition, with the complete documentation of unexpected failures on demand, proof test credit can be taken for the loops involved reducing turn-around time activities.

|

|

|

|

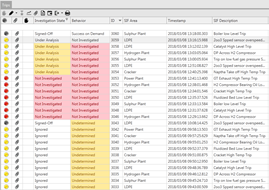

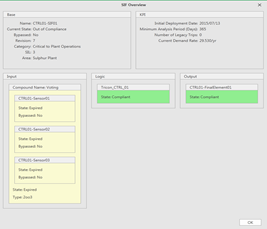

SIF Manager (which includes SIF manager Trip Analyser functionality) is specifically designed to perform the SIF analytics mandated by IEC-61511 Edition 2 – Clause 16. Specifically, the requirement to monitoring, record and validate actual SIS performance against original design requirements to ensure that the SIL integrity of the SIF is not degraded. SIF manager performs all the data gathering, SIF analytics and compliance validation automatically and in real-time, thus providing an automated and persistent system that provides the user with the information he needs about the SIF performance, with minimal hue intervention – significantly reducing the cost of compliance and release (potentially) thousands of high skill man hours back to core production activities.

SIFM mainly provides SIF Demand rate performance, SIF Bypass performance, SIF Trip Performance, SIS Device bypass performance, Device fault tracking, Trip performance statistics, Device failure statistics, Live SIF, SIS device and Trip statistics, SIS device proof test tracking, SIS Device fault tracking, Dynamic PFD Calculation and SIF Condition detail are some of the key benefits we can achieve by using SIFM. |

|

|

|

IPL Manager (which includes SIF Manager functionality) is specifically designed to extend SIF Manager functionality by integrating non-SIS layers of protection (such as BPCS, alarms, mechanical devices etc.) with the SIOF analytics, thus recording, monitoring and analyzing all IPL’s on site. This data is then used in Safety Advisor to assess the dynamic risk profile of every hazardous Event being mitigated by the various IPL’s.

SIF Manager Trip Analyser, SIF manage and IPL Manager – all reside on-premise at each plant. The analytics performed, and insight provided by these systems is focused on SIF/Loop/IPL performance and compliance for that site. |

|

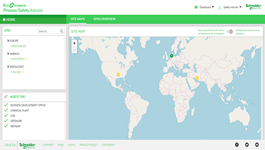

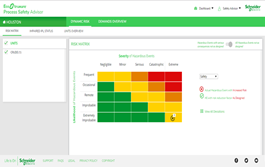

Process Safety Advisor takes the data from IPL Manager and brings this data into a cloud environment where data from many sites/plants aggregated into a single user interface that spans the entire enterprise. I also add another layer of analytics that connects the IPL performance to the actual risk profile for each hazardous Event.

Real-time dynamic risk view helps corporate and operations personnel to make better decision, faster and with confidence. Consolidation of performance insight from multiple plants into a single user interface provides unambiguous digital evidence of plant status & performance, allowing effective collaboration and issue resolution.

Every connected plant can realise immediate commercial benefit by recovering lost production, reduce outage time, reduce unnecessary testing, reduce cost of compliance, reduce human intervention/effort and release high skill resources back to core production. As such best practice on any one site can be effectively and quickly propagated to other sites and the value is can be quickly multiplied across the enterprise. Provides digital evidence to insurers and regulators – allows customers to quickly demonstrate their safety performance and operate safety, profitably and sustainably.

|

|

|

|

|

|

In short – IPL Manager is an on-promise system that provides “loop” based analytics, records and monitoring for a single site, whereas Safety Advisor expands that into a dynamic risk-based view that can span multiple sites no matter their location. |

|

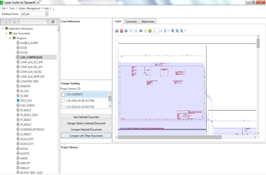

EcoStruxure System Advisor – Process Safety helps improve operational integrity and insight by providing enhanced configuration documentation, change tracking, and I/O management for Triconex® systems for tracking changes and IO management. Safety Advisor helps us to elevates productivity, improves performance, increase quality, reduces re-work and enhances auditing and regulatory compliance. |

|

| Safety View is world’s First TÜV certified software-based Alarm & Bypass Management Operator Interface system. Safety View Monitor and respond to critical process alarms, perform and manage SIF Bypass Management for critical situations and plant maintenance activities, independent of DCS and is TÜV certified for SIL3 application, flexible and less costly than traditional process alarm annunciator panels. |  |

Thus, in short, SE provides complete Safety solutions and services, based on IEC 61511 – Functional Safety Lifecycle that covers all phases of any project starting from Analyse & Assess, Realise & Implement to Operate & Maintain phases.

Link copied. Please paste this link to share this article on your social media post.

Link copied. Please paste this link to share this article on your social media post.

Posted: 2020-12-11 07:42 AM

Thank you for sharing!

Rodrigo G.

Industrial Automation Community manager

Link copied. Please paste this link to share this article on your social media post.

You’ve reached the end of your document

Create your free account or log in to subscribe to the board - and gain access to more than 10,000+ support articles along with insights from experts and peers.