Panel Server / Power Operation

Gateways and Energy Servers

Schneider Electric support forum to share knowledge about product selection, installation and troubleshooting for EcoStruxure Panel Server, PowerTag, Com'X, Link150…

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

| User | Count |

|---|---|

| 82 | |

| 46 | |

| 29 | |

| 28 |

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Panel Server / Power Operation

Dear all,

is there a Device Type / Device Profile in Power Operation for Panel Server, or LINK150?

If not, what is the simpliest way for this intergration?

Thanks in advance.

Best regards

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

I haven't played with the Panel Server yet, but the Link150 is just a gateway. The device profile needs to be built for the downstream serial device. When you add the device using the I/O Device Manager, add it as "Modbus/RTU via Gateway" (assuming Modbus protocol) using the Link150's IP address as the gateway and the device's Modbus address for the device address.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Downstream serial devices are ZBRN2.

Is there device profile for it?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

That makes things more difficult because the ZBRN's Modbus register list depends upon the Zigbee devices connected to it, as I understand. I've never had to deal with one of these in the field.

I don't see any existing device types that use the ZBRN (aside from the SMD, which requires a separate PLC). If you expect to have a large number of downstream devices, I would recommend building a device type in Profile Editor using functional addressing so the type only needs to be built once, then can be added into the project with the correct offsets.

Unfortunately, I don't know if anyone has done this before for the Zigbee devices connected to a ZBRN2.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Hello,

With ZBRN you have 2 modes of operation :

- each sensor is accessible as a modbus device (one modbus id) and depending on the type of sensor you are always having the same register table. You are able to select the starting modbus Id based on table selection.

- each sensor is accessible at register address increment at always the same modbus ID. For TH/CL address increment is +33.

Not sure if it helps.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Hello @milica_dukic_ ,

If you are using a PAS600L or PAS800L, you have 2x DI integrated in the device: In this case you may need to create a new Profil using MODNET or PWRMODBUS drivers to access DI cumulated values (WAGES or Breaker Status).

Internal Panel Server registers are provided with the PAS Modbus file.

Link150 have no exploitable Modbus registers.

If your architecture is Panel Server + ZBRN2 + CL110 / TH110, check following posts:

- https://community.se.com/t5/Gateways-and-Energy-Servers/How-to-get-Modbus-register-of-the-Wireless-T...

- https://community.se.com/t5/Gateways-and-Energy-Servers/Connect-Zigbee-to-LINK150/m-p/373011

Regards,

Regards,

Solution Architect - France Operations

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Hi everyone,

First of all, thanks for answering so quickly.

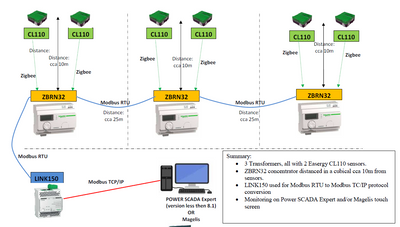

My architecture is shown below.

I would say thats the same thing @Romain_Polette said?

Please correct me if i am wrong.

Best regards,

Milica

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

Hello @milica_dukic_ ,

please check:

- This post: https://community.se.com/t5/Gateways-and-Energy-Servers/How-to-get-Modbus-register-of-the-Wireless-T...

- the Modbus section of the ZBRN2 guide (focus on p. 107).

You will learn how to implement ZBRN2 registers into your Device Profile

For example if you want to read Temp + Hum of CL110 number 0 and 1 paired with the ZBRN2 you need to read:

- register address 16 => sensor 0 temp

- register address 17 => sensor 0 relative hum.

- register address 49 (=16+33) => sensor 1 temp

- register address 50 (=17+33) => sensor 1 relative hum.

- register address 82 (=49+33) => sensor 2 temp

- register address 83 (=50+33) => sensor 2 relative hum.

- etc.

Regards,

Solution Architect - France Operations

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Email to a Friend

- Report Inappropriate Content

Link copied. Please paste this link to share this article on your social media post.

If you are using ZBRN32, you might have to handle the timeout information, less required for CL110 as battery power. Just keep in ming that ZBRN32 will provide the last measurement received (if one was received) or 0 if no measurement yet received. Timeout = 1 means that the value is not refreshed.

Create your free account or log in to subscribe to the board - and gain access to more than 10,000+ support articles along with insights from experts and peers.